Test facilities

Behind the scenes of precision

In our test facilities, we determine specific parameters such as sound power, sound insulation, and vibrations. In addition, supporting product development is a key area of our work. Here, we draw on our many years of experience in consulting in the fields of industrial noise control and technical acoustics.

Read more about:

Test bench for determining dynamic stiffness

The test rig for determining the dynamic stiffness of elastic elements at Müller-BBM in Planegg offers precise and reliable measurements to reduce structure-borne noise and vibration transmission from machinery. Our facility is specifically designed for testing spring elements used in railway superstructures, special shipbuilding, and automotive engineering.

Your Benefits:

- High-Precision Measurements: Our system enables accurate determination of dynamic spring stiffness in both compression and shear directions, ensuring reliable results.

- Versatile Applications: The test rig is suitable for various applications, including building isolation and research projects, and complies with international standards such as ISO 10846 and ENV 13481-6.

- Experienced Specialists: Our trained team ensures professional execution of tests and provides comprehensive support in analyzing and evaluating the results.

Test Rig Specifications:

- Specimen dimensions: up to 600 mm × 600 mm × 900 mm (W × D × H)

- Maximum vertical static preload: 180 kN

- Maximum dynamic force amplitude: 2 kN

Applicable Standards:

- ISO 10846-1 / ISO 10846-2 / ISO 10846-3 / ENV 13481-6 / DB TL 918 071 / BN 918 235 / BN 918 145-1

Do you have any questions?

Feel free to reach out to me!

-

Ingmar Pascher

Ingmar Pascher+49 (89) 85602-198 +49 (89) 85602-111 ingmar.pascher@mbbm-ind.com Planegg/Munich

Impedance tube

We offer precise measurements of the sound absorption coefficient and reflection factor using standardized impedance tubes according to ISO 10534. Our impedance tubes enable the determination of the specific acoustic impedance of a test object under normal incidence and the calculation of both the reflection factor and sound absorption coefficient.

Your Benefits:

- High-Precision Measurements: Our impedance tubes provide accurate determination of specific impedance, reflection factor, and sound absorption coefficient.

- Versatile Applications: With various sample dimensions and tailored frequency ranges, our impedance tubes cover a wide range of applications—from 25 Hz to 6,300 Hz.

- Advanced Methods: In addition to measuring the sound absorption coefficient, we can also determine transmission or sound insulation index R₀ through a component under normal incidence, enabling comprehensive acoustic analysis.

| Impedance tube | Sample dimensions | Frequency range |

| 1 | square 600 mm x 600 mm | 25 Hz...250 Hz |

| 2 | circular, diameter 100 mm | 90 Hz...1.900 Hz |

| 3 | circular, diameter 30mm | 500 Hz...6.300 Hz |

Do you have any questions?

Feel free to reach out to me!

-

Sonia Alves

Sonia Alves+49 (89) 85602-3147 +49 (89) 85602-111 sonia.alves@mbbm-ind.com Planegg/Munich

Vehicle acoustics - anechoic room

Müller-BBM Industry Solutions GmbH offers a state-of-the-art test facility for vehicle acoustics at its Planegg location. Our semi-anechoic room enables precise acoustic measurements on vehicles without interference from external noise.

Your Benefits:

- Precise Measurements: Thanks to sound-insulating installations and the structural separation of the acoustic test room, measurements can be performed without external noise interference.

- Versatile Analysis Capabilities: Our flexible measurement systems are suitable for all types of acoustic and vibration analyses and can be adapted to specific tasks, including: Active Sound Design, Structural dynamics and modal analysis as well as Intensity measurements.

- Comfortable Test Conditions: Climate control via a multi-stage ventilation system and exhaust extraction ensure optimal test conditions, allowing measurements on vehicles with or without engine operation.

Room Specifications:

| Internal dimensions | 8 m × 7 m × 3 m |

| Entrance door opening | H = 2.6 m, W = 4.0 m |

| Ventilation capacity | up to 7,500 m³/h |

| Background noise level | < 20 dB(A) |

Measurement and Analysis Systems:

- PAK® multi-channel measurement system

- Active Sound Design system (ASD)

- Structural dynamics and modal analysis system (various shakers, impact hammers, software)

- Intensity measurement system

Do you have any questions?

Feel free to reach out to me!

-

Alex Sievi

Alex Sievi+49 (89) 85602-208 +49 (89) 85602-111 alex.sievi@mbbm-ind.com Planegg/Munich

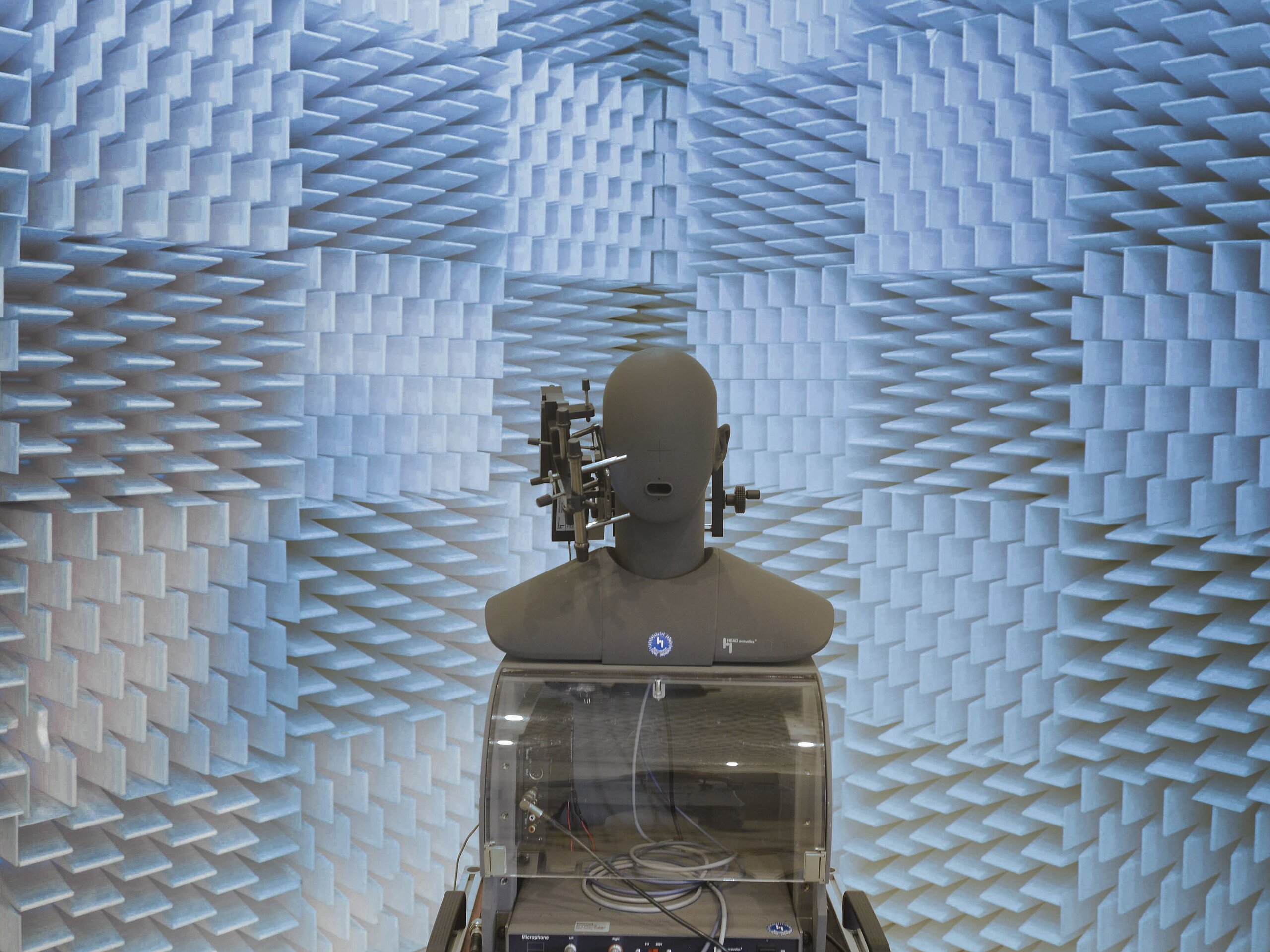

Anechoic halfspace

The hemi-anechoic room at Müller-BBM Industry Solutions GmbH in Planegg provides an optimal environment for analyzing acoustic issues and supporting your product development. Our state-of-the-art test facility enables precise sound power measurements and the analysis of extremely quiet noise sources.

Your Benefits:

- Maximum Precision: Thanks to the special “room-in-room” construction and elastic mounting, we achieve very high sound insulation. Even during daytime, the background noise level is only around 0 dB(A). This allows for standard-compliant and highly accurate determination of sound power from noise sources.

- Versatile Analysis Capabilities: Our test facility is designed for Grade 1 sound power measurements according to ISO 3745, for test objects up to a volume of 0.45 m³ – roughly the size of a washing machine – covering a wide range of applications.

- Advanced Analysis Functions: By amplifying recorded signals, operational noises can be examined as if through an “acoustic magnifying glass.” Our advanced multi-channel measurement technology and PAK® analysis software enable detailed and comprehensive evaluations.

Do you have any questions?

Feel free to reach out to me!

-

Otto Martner

Otto Martner+49 (89) 85602-225 +49 (89) 85602-111 otto.martner@mbbm-ind.com Planegg/Munich

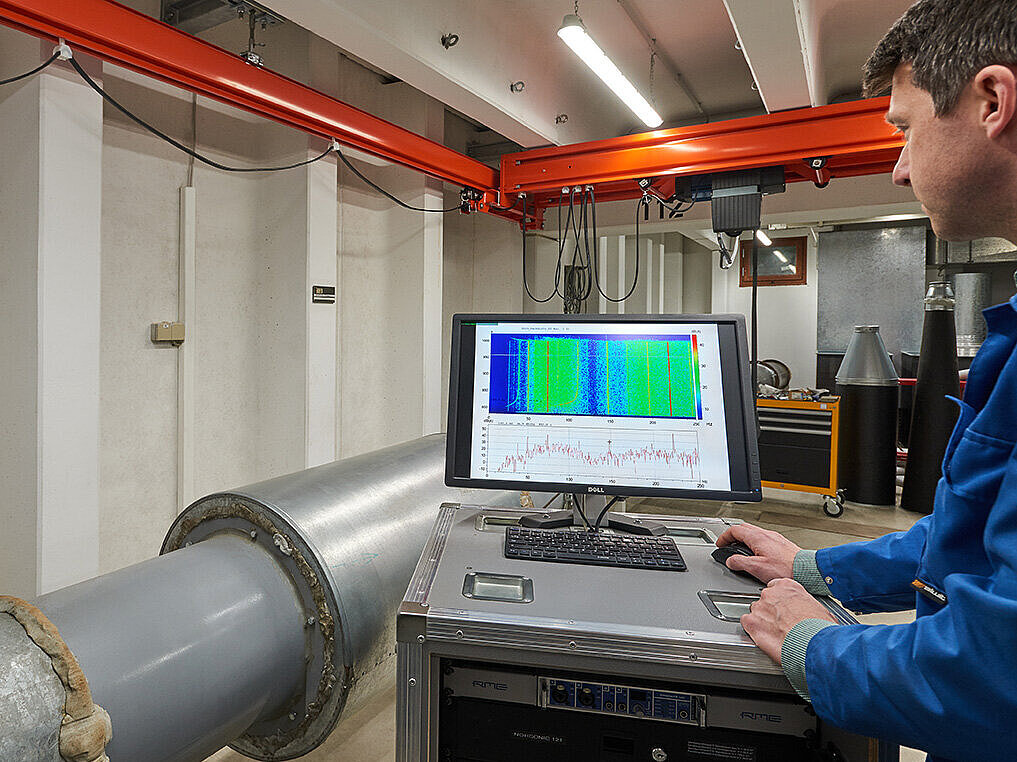

Pipeline test

The pipeline test rig of Müller-BBM Industry Solutions GmbH enables precise measurements of the spectral insertion loss of pipe insulation systems under laboratory conditions according to ISO 15665.

Your Benefits:

- Safety and Optimization: Our investigations provide planning reliability and economic optimization for the acoustic design of industrial plants as well as for product development.

- Flexibility in Pipe Diameters: The acoustic performance of insulation systems depends, among other factors, on the pipe diameter. The test rig includes three test pipe diameters: DN100, DN300, and DN600, covering the size classes defined by the standard and allowing flexibility for insulation configurations.

- Versatile Test Methods: In addition to the reverberation room method for determining the insertion loss of insulation systems, we also offer the intensity measurement method, e.g., according to ISO 9614-2. This ensures high quality and reliability of the results, even for highly effective insulation systems, such as those designed for the newly introduced Class D of ISO 15665.

Do you have any questions?

Feel free to reach out to me!

-

Marco Geisler

Marco Geisler+49 (89) 85602-3004 +49 (89) 85602-111 marco.geisler@mbbm-ind.com Planegg/Munich

Silencer test bench

Our test rig enables precise laboratory measurements of silencers in ducts according to DIN EN ISO 7235. It allows determination of both the acoustic insertion loss and the pressure drop across the silencer, as well as the flow noise generated at defined air volume flows. Acoustic measurements are conducted in a reverberation room in accordance with ISO 3741.

Your Benefits:

- Safety and Optimization: Our investigations provide planning reliability and economic optimization for the acoustic design of industrial plants as well as for product development.

- Modular Design: The test section is modular, allowing a wide range of silencer geometries and types to be tested, such as:

- Baffle silencers in their own housing

- Individual baffles

- Duct silencers (with and without core)

- Measurements with Airflow: In addition to purely acoustic excitation, the test specimen can be subjected to an airflow of up to approx. 15,000 m³/h. This enables representative measurement of pressure loss and self-generated noise under flow conditions.

Do you have any questions?

Feel free to reach out to me!

-

Marco Geisler

Marco Geisler+49 (89) 85602-3004 +49 (89) 85602-111 marco.geisler@mbbm-ind.com Planegg/Munich